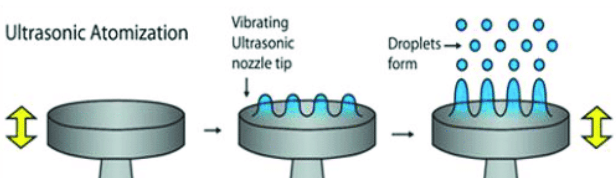

Thanks to its ultrasonic process, PUS produces on Technopole of Savoie Technolac in France, spherical powders with low and controlled oxide layer, without ultra fines and dust. The sieving step allows an efficient and narrow classification.

The proposed ranges of alloys are the following:

The available particle size diameters in these different alloy’s ranges are from Type 3 to Type 6

High level of sphericity: absence of oblongs or satellites

Strong control of oxide layer: It leads to repeatability and Good compatibility with chemistry of the solder pastes formulas (no paste viscosity increase, longer shelf life …)

High Repeatability from lot to lot

Free of ultra-fines and dust: Less oxygen level, good solder balling test leading to no short circuit risk

Advantages of the UT technology: Spherical shape, Sharp particle size repartition

Advantages ultrasonic sieving: good particle size diameter repartition, good cut

© 2023 «PUS Pure Ultrasonic System» tous droits réservés. Réalisation : 8PIXL maintenance : ma-maintenance-wordpress.fr